In a 3 Coat System Which Coat Normally Uses Zinc

Roofs are made of Zinc while some pipelines are coated with Zinc. The last coating material applied in a coating system specifically formulated for aesthetics andor environmental resistance.

Measurement Results Of Zinc And Phosphate Coating Weight And Dry Paint Download Table

These primers can be either zinc rich or reduced zinc types.

. Gray Zinc-Sele is designed to be used as a two-coat system for exterior exposures subject to heat in the temperature range of 300- 800F 149-427C weathering and mild industrial conditions. Great for chemical resistance and high impact durability. The coating has high gloss and high-quality metal appearance.

Adheres well to bare steel and inorganic zinc silicate coated surfaces on new construction projects consisting of structural steel bridges. This product complies with USDA FSIS regulatory sanitation performance standards for food. Blast clean to a minimum Of Sa 212 Swedish Standard SIS 05 5900 with a surface profile not exceeding 3540 microns.

One or more layer of metal on a steel base base material. Metallic Zinc with a Finishing Layer ISO 2004. The surface should be clean and dry before application Of Zinc Anode 304.

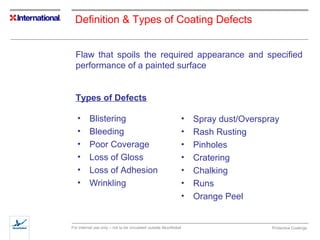

Over time the porosity is filled with corrosion products and barrier effect increases. B A light coat of unspecified DFT to temporarily inhibit corrosion see Section 342. 114 Mudcracking A surface condition characterized by cracks that extend into.

Zinc coatings provide excellent corrosion protection to structural steel. Zinc mineral is used in the treatment of the prostate. The use of untopcoated zinc-rich systems is discussed in Section 5.

Intact inorganic zinc silicate coatings provide protection to the steel substrate by the barrier effect of the zinc silicate. Tie coats are used to seal the porous surface eg zinc-rich primer to bond generically different types of coatings or to improve the adhesion of a succeeding coating. To simplify the application parameters for a system based on zinc-rich primers on new steel bridges a series of charts has been developed.

Coated with 3 coat systemPolymer Systems for Performance Commercial Industry Involvement Testing Offshore WB HRZS Commercial Industry involvement Offshore Ply Zinc WB18 is currently in an on site approval evaluation for use as a single coat Corrosion Inhibitor system in the GOM. 13 Breaking the Corner Corner Chamfering A process by which a. Different coats of paint that can be associated in a painting system or other coating systems without producing undesirable effects are also compatible.

This standard was first published in 1985 and requires application of high purity zinc minimum of 9999 by mass. VZ-108D must be properly mixed with all three components in the proper ratios or the primer approved by the US. And the use of topcoated systems is discussed in Section 54.

The zinc dust needs to electrically connect with the steel surface to provide cathodic protection as the coating chemically reacts with the surface. VZ-108D is an organic zinc-rich primer for direct application to properly prepared steel surfaces. The zinc corrosion results are normally the mean of 18 determinations 3 replicates for 6 1-year exposures starting in spring and autumn for 3 years.

The most frequently used zinc coating thickness measurement methods are magnetic methods in accordance with the ISO 2178 technical standard. Zinc phosphate epoxy primers are the most frequently encountered and give the best durability within the group. Product used in the photo is Gulf Coast Paints MCU-104 Zinc Rich Primer.

During galvanization Zinc is used as a chief preventer of rusting in metals and iron. 42 VEHICLES FOR ZINC-RICH COATINGS. Perhaps the most practical method of determining a suit-.

System 3 Polysiloxane Weatherable epoxy that embodies the properties of both a high performance epoxy and an acrylic polyurethane in one coat polysiloxane. Adding a priming step to your process can help defeat problems with adhesion poor surface quality uneven surfaces and orange peel. Army Corps of Engineers in the following coating systems at the indicated DFT.

Application of a spray coat of metal usually zinc or aluminum onto a prepared surface. Metallic zinc coating on ductile iron pipe is normally applied in accordance with ISO 8179-1 Ductile Iron Pipes-External Zinc-Based Coating-Part 1. Chemical Processing Pulp and Paper Food Beverage Processing Power Generation.

Also referred to as a finish coat. Coating systems it is wise to use portions of the original coat-ings which have been saved for this purpose or to procure additional amounts of the original coatings. Its shoots and coats like other powders.

These 3 types of coatings are some of the most common that you will see in industrial markets such as. In this system a zinc electrode anode. Areas are in the splash zone and.

This will ensure compatibility of the repair system with the existing coating system. Inorganic zinc must be applied to an abrasive blast-cleaned surface with a high standard of cleanliness. The 3-coat system is the most common applying a prime coat a color or base coat and a texture coat.

Zinc is a key constituent in corrosion control paints. This Guide Specification represents a consensus on best industry practice for shop application of zinc rich coating systems to previously uncoated bridge steel and includes the proper preparation of the steel. Zinc rich primers produce films which contain about 85 by weight of metallic zinc powder and the reduced zinc type as low as 55 by weight.

Typical dry film thickness for the 3-coat system ranges from 1 to 3 mils for the prime coat 1 to 2 mils for the color coat and 1 to 5 mils for the texture coat. PretreatmentCyanide-free alkaline copperCyanide-free copper-nickel alloy tinChrome plating advantage. Electroplating technology is widely used in many Both zinc alloy die castings and aluminum alloy die castings can be applied.

This is a good primer for epoxies as well as other powders. Zinc Anode 304 Inorganic Zinc Silicate Coating Remove grease Oil and Other contaminants preferably by using Bison Degreasing Solvent. METALLIZED ZINC COATING ISO-8179.

NFV initial cost 1i. 413 Zinc-rich coatings may be used as a one-coat system or may be overcoated with one or more other coat-ings. The use of zinc-rich coatings as prefabrication primers.

Both are used to calculate the more easily understood and meaningful average equivalent annual cost AEAC for each coating system being modeled for any specific project. Zinc plays a very vital role in restoring damaged reproductive tissues in Men. 12 Best Effort Actions expected of a reasonably knowledgeable person to properly perform an activity.

Guide Specification for Coatings with Inorganic Zinc Rich Primer Section 1 Definitions 11 Applicator Shop A fabricator paint contractor or other entity which prepares the surfaces and applies the coatings. Not for use on aluminum. This coating may also be used for interior surfaces.

Spray coating systems commonly used in this industry fall into 3 categories 3-coat 2-coat and single-coat.

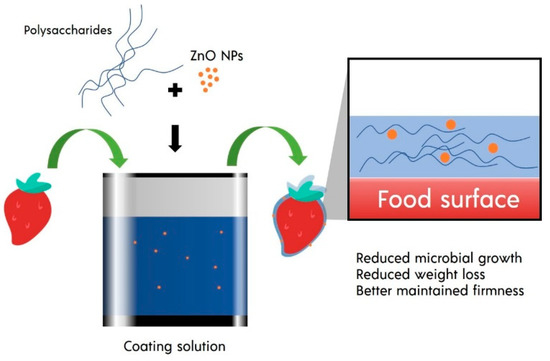

Coatings Free Full Text A Review Of Polysaccharide Zinc Oxide Nanocomposites As Safe Coating For Fruits Preservation Html

Types Of Galvanizing And Other Zinc Coatings

Measurement Results Of Zinc And Phosphate Coating Weight And Dry Paint Download Table

Primer Coating The Fourth Coating Step Is The Primer It Can Be Download Scientific Diagram

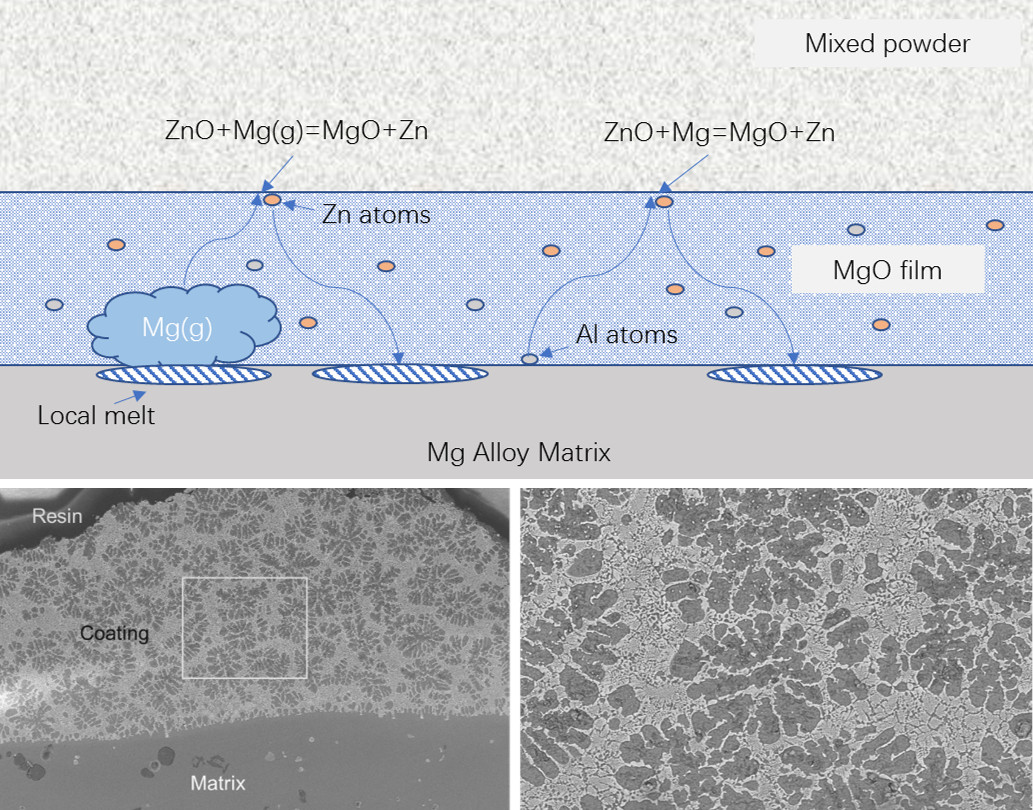

Coatings Free Full Text A Zinc Rich Coating Fabricated On A Magnesium Alloy By Oxide Reduction Html

Heat To Coat Hot Dip Galvanizing Wuppermann Ag

Plastic Coating What Is It How Does It Work Process

链节围栏系统 Pvc或镀锌 Chain Link Fence Fencing Material Zinc Coating

Eco Friendly Corrosion Protection The Potential Of Graphene

The Most Commonly Used Techniques For Coating Fertilizer Granules Download Scientific Diagram

The Underbody Coating The Third Step Is Underbody Coating Seam Download Scientific Diagram

Box Profile 34 1000 Sheets Polyester 0 7mm Roofing Sheets Roofing Sheets Roofing Corrugated Metal Roof

Ed014 Black Coat Hanger Edizioni Design In 2021 Coat Hanger Black Coat Hanger Hanger Design

What Is A 3 Coat Paint System Piping Technology Products Inc

Comments

Post a Comment